0000-00

Introduction: The Critical Role of Precision Equipment in Transformer Insulation

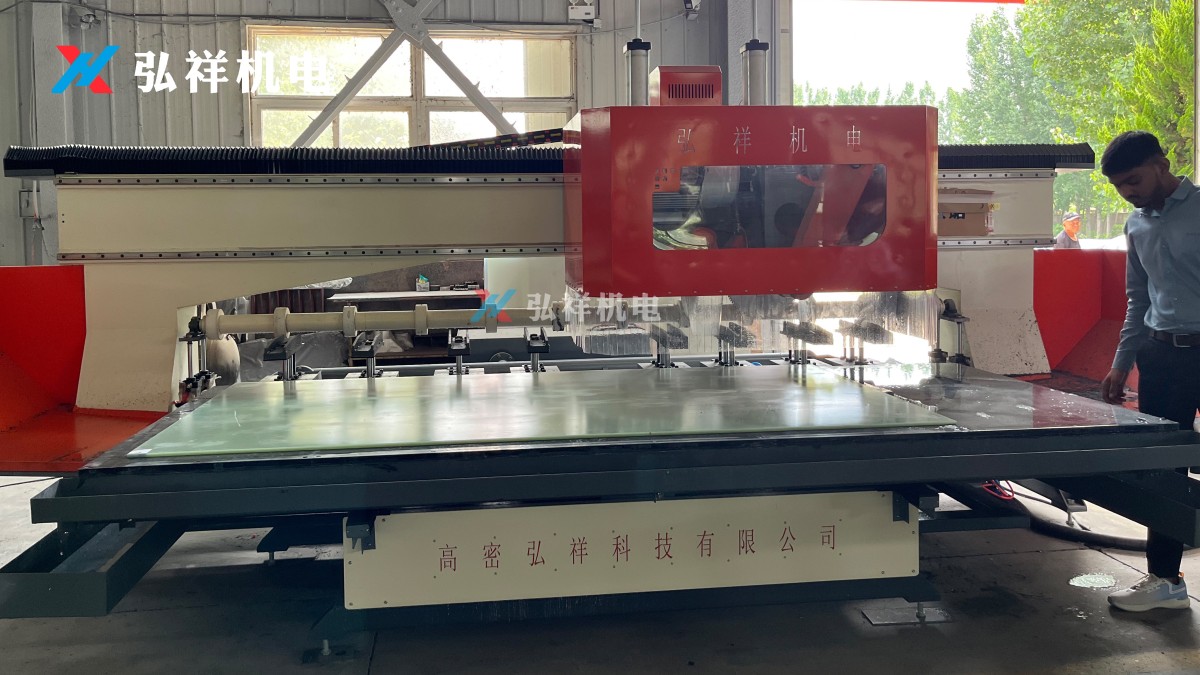

Selecting the right transformer insulation parts processing equipment is critical for efficient electrical insulation applications. Whether you need bulk order solutions, EVA molding capabilities, or custom CNC equipment for laminated wood processing, Gaomi Hongxiang delivers precision-engineered solutions. As a leading Chinese manufacturer, we offer OEM services and specialized machinery for electrical insulation components, serving global clients across power transformer manufacturing. Discover how our expertise in processing insulating cardboard and laminated wood can optimize your production line.

Key Considerations for Selecting Transformer Insulation Parts Processing Equipment

When sourcing transformer insulation parts processing equipment, several critical factors must be evaluated to ensure optimal performance and longevity. Material compatibility stands as the foremost consideration - equipment must be specifically designed to handle electrical insulating cardboard, laminated wood, and EVA materials without compromising dimensional stability or dielectric strength. Production capacity requirements significantly influence equipment selection, with high-volume manufacturers needing robust systems capable of continuous operation, while smaller operations may prioritize flexibility. Precision tolerances are non-negotiable in this sector, as even minor deviations in insulation component dimensions can lead to transformer performance issues or safety hazards. The equipment's automation level should align with your labor resources and quality control protocols, ranging from fully manual systems to advanced CNC transformer insulation parts processing equipment with integrated measurement systems. Energy efficiency has become increasingly important, with modern machines offering power-saving modes and optimized thermal management. Finally, consider the total cost of ownership, including maintenance requirements, spare parts availability, and potential downtime costs, rather than focusing solely on the initial purchase price.

Specialized Equipment for Diverse Insulation Materials

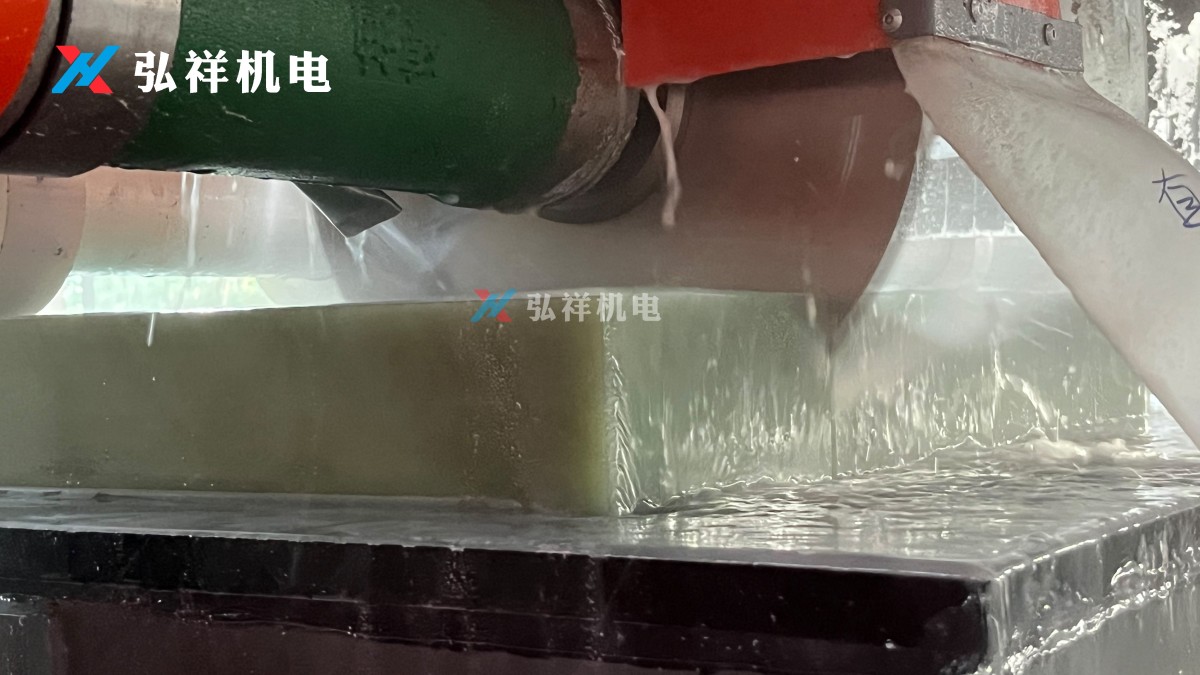

The transformer manufacturing industry utilizes various insulation materials, each requiring specialized processing equipment. For electrical insulating cardboard, precision cutting and forming machines must maintain material integrity while achieving complex shapes. These systems often incorporate laser measurement and computer-controlled knives to ensure accuracy. Laminated wood insulation demands different handling, with equipment for transformer insulation parts processing for laminated wood requiring heavy-duty milling capabilities and dust extraction systems. EVA molding presents unique challenges, necessitating temperature-controlled presses and precise cooling systems in transformer insulation parts processing equipment for EVA molding. Many manufacturers now seek multi-material capabilities in their equipment, allowing flexibility in production while maintaining strict quality standards. The most advanced systems incorporate material recognition technology that automatically adjusts processing parameters based on the insulation material being worked.

Advanced Technologies in Modern Processing Equipment

Contemporary transformer insulation parts processing equipment incorporates numerous technological advancements that enhance productivity and quality. CNC technology has revolutionized the sector, enabling unprecedented precision in custom transformer insulation parts processing equipment. These computer-controlled systems can store hundreds of part programs, allowing quick changeovers between different insulation components. Many machines now feature integrated quality control systems using vision technology to inspect parts during production automatically. Industry 4.0 connectivity enables remote monitoring of equipment performance and predictive maintenance scheduling, significantly reducing unplanned downtime. Some advanced systems incorporate artificial intelligence algorithms that optimize cutting patterns to minimize material waste, particularly valuable when processing expensive insulation materials. For operations requiring high-volume production, automated material handling systems can be integrated with processing equipment to create continuous production lines. These technological advancements have made modern transformer insulation parts processing equipment manufacturer in China offerings competitive with global standards while maintaining cost advantages.

Bulk Order Solutions and OEM Services

For manufacturers requiring transformer insulation parts processing equipment bulk order capabilities, several specialized solutions exist. High-throughput systems designed for 24/7 operation feature redundant components and easy-access maintenance points to maximize uptime. Many suppliers offer customized production line configurations that can be scaled to match growing demand. OEM services have become increasingly sophisticated, with leading manufacturers like Gaomi Hongxiang providing complete engineering support from design through production. These services are particularly valuable for companies developing proprietary insulation components or working with non-standard materials. When evaluating transformer insulation parts processing equipment OEM service providers, consider their experience with similar projects, engineering capabilities, and ability to meet international standards. Many Chinese manufacturers now offer comprehensive OEM packages that include equipment customization, process optimization, and operator training, making them attractive partners for global transformer manufacturers.

Global Sourcing Strategies for Processing Equipment

Transformer insulation parts processing equipment sourcing requires careful evaluation of global suppliers. Chinese manufacturers have emerged as leading providers, offering competitive pricing without compromising quality. When sourcing from China, verify certifications such as ISO 9001 and CE markings, which indicate compliance with international standards. Factory audits, either in-person or virtual, provide valuable insights into manufacturing capabilities and quality control processes. Payment terms and logistics arrangements should be clearly established, with particular attention to after-sales support and technical documentation availability. Many buyers find value in establishing long-term relationships with a reliable transformer insulation parts processing equipment manufacturer in China, as this often leads to better pricing, priority service, and access to the latest equipment developments. For companies new to international procurement, working with local representatives or trading companies familiar with both markets can streamline the process and mitigate risks.

Safety and Quality Control in Insulation Component Manufacturing

Safety considerations are paramount when operating transformer insulation parts processing equipment for electrical insulation applications. Proper machine guarding, emergency stop systems, and operator training programs are essential components of a safe working environment. Dust collection systems are particularly critical when processing laminated wood and other materials that generate fine particles. Quality control measures should be implemented at multiple stages, from incoming material inspection to final product verification. Modern equipment often includes built-in process monitoring systems that track key parameters and alert operators to deviations. Regular maintenance, following the manufacturer's recommended schedule, helps ensure consistent performance and extends equipment lifespan. Documentation of all quality control activities and safety inspections is increasingly important as transformer manufacturers face more stringent regulatory requirements and customer audits. Implementing a comprehensive quality management system that covers equipment operation, maintenance, and output verification helps maintain the high standards required in electrical insulation component production.

Conclusion: Partnering for Insulation Processing Excellence

Selecting and implementing the right transformer insulation parts processing equipment requires careful consideration of technical requirements, production needs, and long-term business objectives. From custom CNC solutions to high-volume production systems, the market offers diverse options to meet various manufacturing challenges. Gaomi Hongxiang Electromechanical Technology Co., Ltd. stands ready to support your transformer component manufacturing needs with our extensive expertise in processing electrical insulating materials. Our comprehensive range of equipment and services, including OEM solutions and bulk order capabilities, is backed by decades of experience serving global power transformer manufacturers.

Contact our engineering team today to discuss your specific transformer insulation parts processing requirements and discover how our solutions can enhance your manufacturing efficiency and product quality.

التنقل

رسالة

طلب عرض أسعار؟